Sustainable stainless steel for Clean Mobility

Esslingen/Mannheim (Germany), Helsinki (Finland), 9 August 2023 – Purem by Eberspaecher, together with its strategic partners Outokumpu and thyssenkrupp Materials Processing Europe, has further intensified its cooperation with regard to CO2 reduced stainless steel. This underlines the joint goal to reduce emissions and drive corporate environmental responsibility.

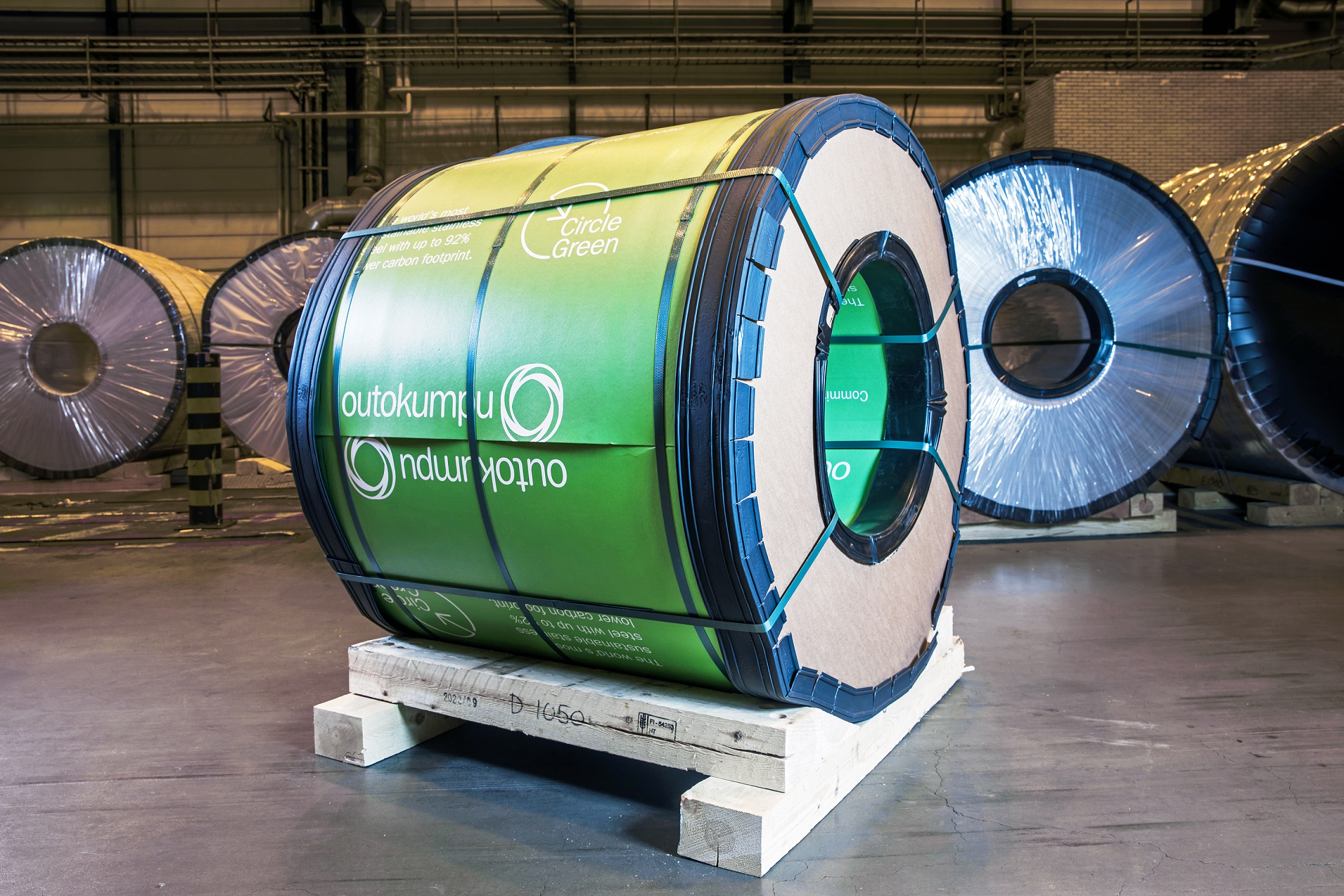

This month, Purem by Eberspaecher starts using “Circle Green” to reduce emissions from the automotive industry. This sustainable stainless steel has an up to 92 percent lower carbon footprint compared to the industry average*. Outokumpu offers this world’s first towards-zero stainless steel. The Circle Green achieves a level of less than 0,6 tCO2e/t steel driven by improvements in the production process, such as the use of a higher recycling rate, CO2 free energy sources, as well as CO2 optimized distribution channels.

Purem by Eberspaecher is aware of its responsibility towards the environment and society and is therefore intensifying the cooperation: “With clear goals for a CO2 neutral production by 2030 and becoming a CO2 neutral company in the future, we drive forward proactively the use of sustainable materials in our products. Towards zero emissions, stainless steel plays a major role in our current products as well as future innovations for new drive technologies like the hydrogen engine”, underlines Uwe Ackermann, Vice President Global Procurement, Purem by Eberspaecher.

The partner Outokumpu highlights: “We are committed to circular economy. No other stainless steel manufacturer has achieved such low emission levels throughout the entire production chain from raw material extraction to final production. We are happy to intensify the collaboration with Purem by Eberspaecher, offering solutions to strive more sustainable mobility”, says Niklas Wass, Executive Vice President, Stainless Europe, Outokumpu.

The first shipment of the material was already delivered by service partner thyssenkrupp Materials Processing Europe to the Purem by Eberspaecher Wilsdruff plant. Here, the more sustainable stainless steel will be processed into commercial vehicle exhaust systems with a reduced CO2 footprint. This is an important step towards reducing Scope 3** emissions at Purem by Eberspaecher.

“As a strong service partner – especially in the automotive sector – thyssenkrupp Materials Processing Europe is actively addressing the ambitious challenges and targets in the industry. Our teams accompany the innovative research and development of our customers from the very beginning and supports within the supply chain to achieve the formulated emission targets. As a central link between manufacturer and Purem by Eberspaecher, we look forward to the further development in the automotive segment and are pleased to be able to accompany our long-standing customer as a partner at their side for this milestone”, says Marcus Woehl, CEO, thyssenkrupp Materials Processing Europe.

Overall sustainability approach with clear targets

Adapted purchasing strategies – that include Outokumpu standard stainless steel with the highest recycling rate in Europe and producing with green energy (1,7 tCO2e/t Steel) – will achieve just in Europe further savings of up to 12 percent in CO2 emissions this year. Thus, the approach to use Circle Green in the future is a consistent continuation of the supplier's sustainable purchasing strategy. Advanced talks are currently underway with key automotive manufacturers to use CO2 reduced as well as Circle Green in series production. In this way, Purem by Eberspaecher is actively shaping the transformation towards sustainable materials.

Purem by Eberspaecher as Division of the Eberspaecher Group bundles its future-oriented sustainability activities in the Green Footprint, Innovation, and People areas of activity. The non-profit organization CDP has confirmed their effectiveness with a “B Score” in its annual assessment. Since reporting began in 2019, the Group has reduced its global production-related CO2 emissions by 45 percent. Detailed information about the responsibility and sustainability activities can be found on the website and in the 2022 sustainability report.

*Global average CO2 emissions 6.1 tons of CO2 per ton of stainless steel. Outokumpu Circle Green CO2 emissions: up to 0.5 tons of CO2 per ton of stainless steel.

**Scope 3 emissions comprise all indirect greenhouse gas emissions that are not directly caused by the company but are attributable to its business activities.

Global Media Contact:

Anja Kaufer

Vice President Corporate Communications

Eberspächer Group

Phone: +49 711 939-0250

press@eberspaecher.com

Further Media Contacts:

Outokumpu media desk,

Phone: +358 40 351 9840, media@outokumpu.com

thyssenkrupp Materials Services media: Lars Bank, Head of Communications,

Phone: +49 201 844 534416, lars.bank@thyssenkrupp-materials.com

***

About Purem by Eberspaecher:

Purem by Eberspaecher is a subsidiary of the Esslingen-based Eberspaecher Group. To achieve clean and quiet mobility, more than 7,100 employees develop and produce exhaust and acoustic systems for passenger cars, CVs, and off-road vehicles. The technologies make a significant contribution to meeting the strictest emission standards and noise guidelines. Its customer base includes the world’s leading vehicle manufacturers. In 2022, the area within the group of companies generated revenue of around 5.7 billion euros. Net revenue adjusted for transitory items amounted to 1.9 billion euros.

About Eberspaecher:

With approximately 10,700 employees at 80 locations worldwide, the Eberspaecher Group is one of the automotive industry’s leading system developers and suppliers. The family business, headquartered in Esslingen am Neckar, stands for innovative solutions in exhaust technology, automotive electronics and thermal management for a broad range of vehicle types. In combustion or hybrid engines and in e-mobility, the components and systems from Eberspaecher ensure greater comfort, higher safety and a clean environment. Eberspaecher is paving the way for future technologies such as mobile and stationary fuel cell applications, synthetic fuels as well as the use of hydrogen as an energy carrier. In 2022, the Group generated revenue of around 6.4 billion euros. Net revenue adjusted for transitory items amounted to 2.7 billion euros.